-

English

-

French

-

Korean

-

Portuguese

-

Russian

-

Spanish

English

French

Korean

Portuguese

Russian

Spanish

In today's race toward a carbon-neutral world, energy storage systems (ESS) are no longer a luxury — they're the backbone of modern energy infrastructure.

And among all configurations, one design has rapidly risen to the top: Containerized, modular ESS. It's fast to deploy, easy to scale, and designed for the unpredictable energy future ahead.

So what makes modular containerized ESS the new industry standard? Let's dive in.

Not long ago, large-scale battery projects were built like power plants —

Custom buildings, months of civil works, and endless coordination between battery, inverter, and BOS suppliers.

Today, that's changing.

Containerized ESS shifts the paradigm from field construction to factory integration. Each 20 ft or 40 ft unit arrives pre-assembled, pre-tested, and ready to plug in.

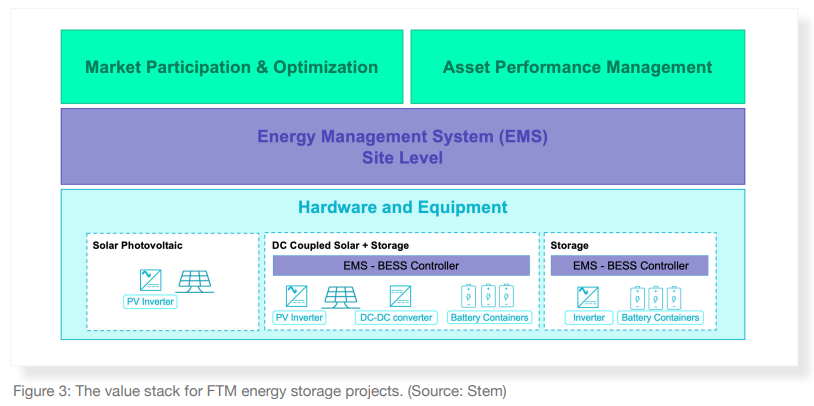

A modular approach to front-of-the-meter storage has emerged — allowing developers to mix & match hardware from different vendors and shorten time-to-market. — Stem, Inc. eBook (2024)

This model has become the go-to standard for commercial, industrial, and utility projects worldwide.

Need 2 MWh today but 10 MWh next year? Just add more containers — no redesign required.

This “building-block” concept lets projects grow with energy demand while keeping the same footprint and interface.

Containerized ESS can be installed in days, not months. Factory testing means fewer site surprises and faster commissioning — a clear advantage where grid-connection windows are tight.

Because production happens in a controlled, factory environment, every process — from battery stacking to busbar welding — is optimized for consistency and scale.

Labor costs drop thanks to automation and repeatable workflows. Material waste is minimized, with precision manufacturing and tighter QA standards. Rollout can be phased, allowing investors to align deployment with cash flow and local market incentives instead of a single massive CAPEX outlay.

Beyond initial savings, modular ESS also reduces lifetime ownership costs: standardized parts simplify maintenance, shorten downtime, and allow quicker swap-outs when technology upgrades arrive.

In short — you save twice: once at installation, and again every year in operation.

Modular containers follow standard footprints and interfaces. That means easier certification, faster logistics, and simplified maintenance — the very things EPCs and O&M teams love.

Each container is self-contained and transport-ready. Whether for remote microgrids, C&I parks, or emergency backup, they can be redeployed or repurposed in a matter of days.

According to Data Intelo, the container-type ESS market is projected to grow from USD 4.5 billion in 2023 to USD 12.7 billion by 2032, fueled by demand for scalable and relocatable storage.

And with battery costs down 90 % over 15 years (IEA 2024), the economics have never been more compelling.

For industrial and commercial users — factories, data centers, logistics parks — modular ESS offers:

In short: deploy now, grow when ready.

Even the best designs need attention to detail.

🔸 Thermal management and fire suppression must be carefully engineered inside compact enclosures.

🔸 Integration across multiple containers demands a capable EMS/BMS for balancing and coordinated control.

🔸 Permitting and site logistics — cranes, road access, interconnection — still need local expertise.

“Modularity adds flexibility, but also complexity in orchestration.” — Stem eBook, 2024

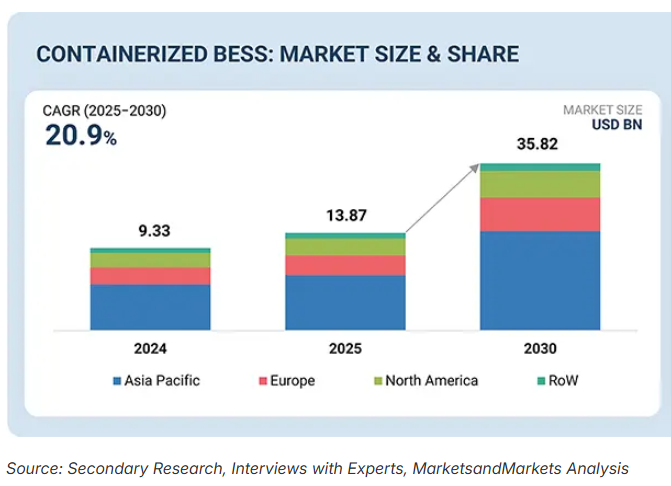

The global containerized BESS market is projected to grow from USD 13.87 billion in 2025 to USD 35.82 billion by 2030, at a CAGR of 20.9%. This robust growth is fueled by the increasing integration of renewable energy sources, the rising demand for grid flexibility, and the need for reliable backup power across residential, commercial, and utility sectors. The next generation of containerized ESS is already here:

Higher-energy modules — 20-ft containers exceeding 5 MWh capacity.

Smarter software — EMS platforms that coordinate dozens of parallel units.

Global mobility — serving APAC, Africa, and Latin America where deployment speed is critical.

Circularity — easier repurposing, relocation, and recycling of end-of-life containers.

The message is clear: the energy future will be modular.

Containerized ESS isn't just a technical improvement — it's a new philosophy of energy infrastructure. Fast, flexible, and scalable.

As global demand for reliable power accelerates, modularity will be the key to bridging today's energy challenges with tomorrow's clean-power reality.

So, the next time you design a storage project, ask yourself:

“Can it be modular?”

If the answer is yes — you're already building the future.

Explore the latest news and technology trends in the energy storage industry.